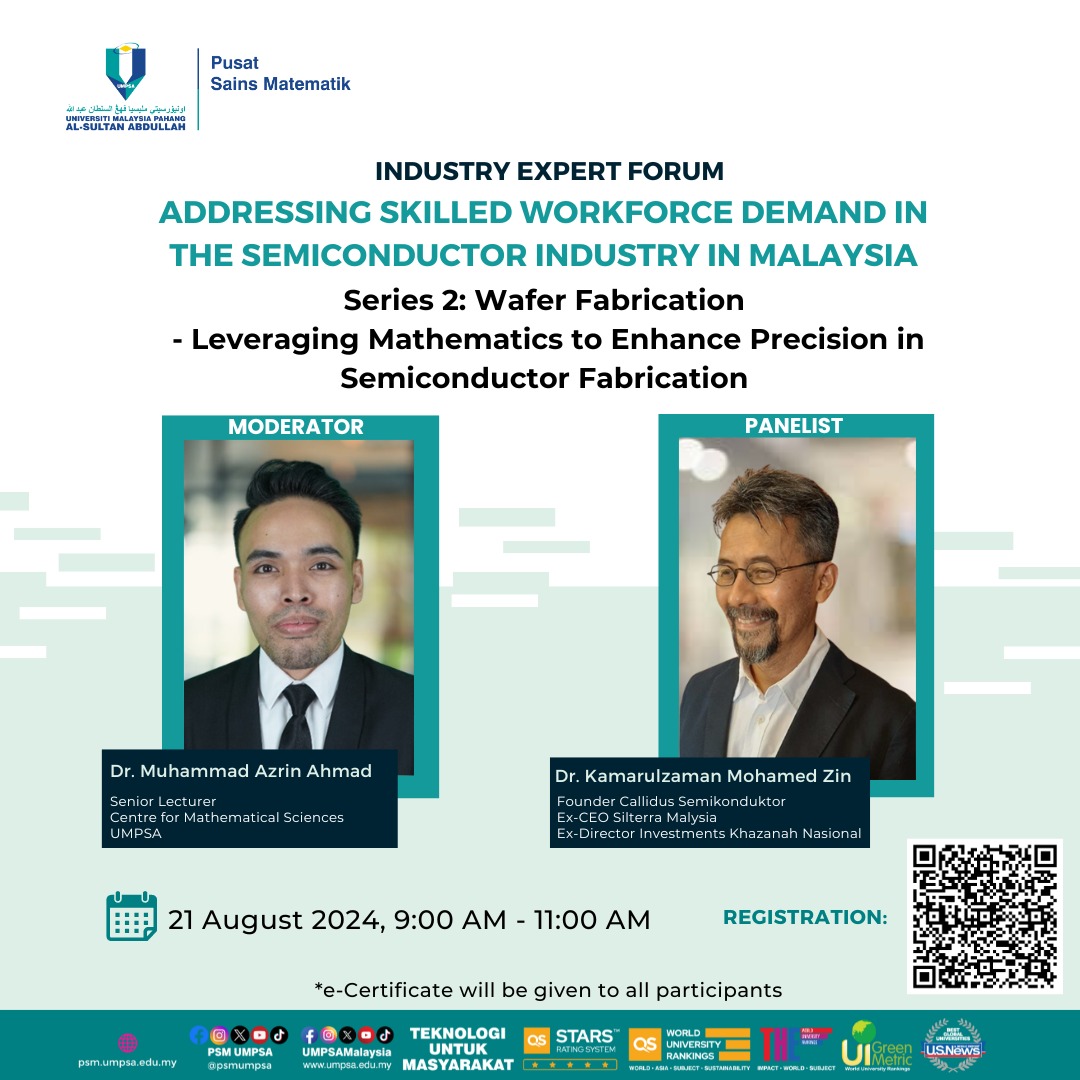

Forum II Series: Wafer Fabrication – Leveraging Mathematics to Enhance Precision in Semiconductor Fabrication

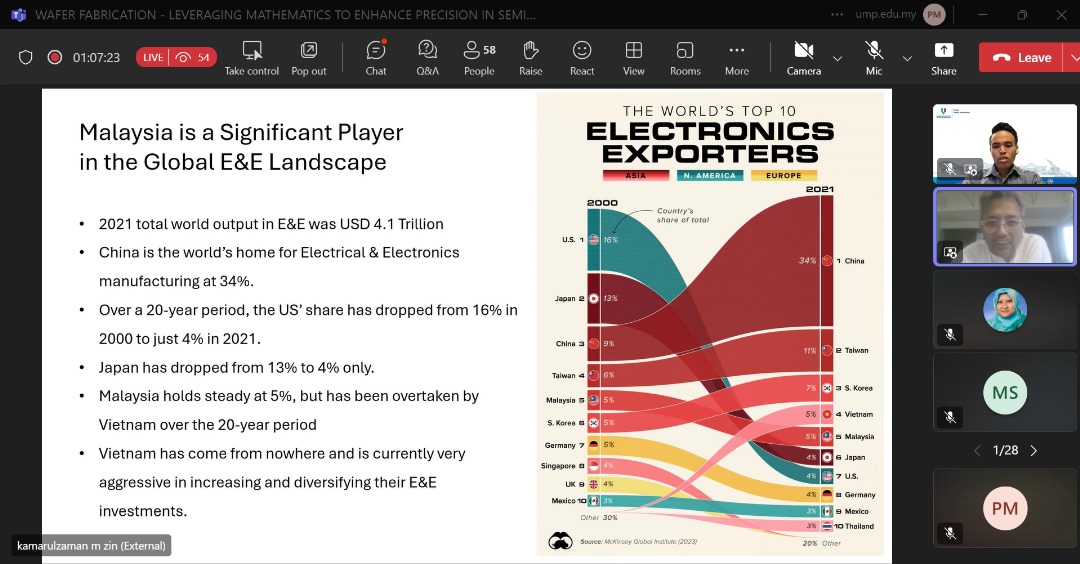

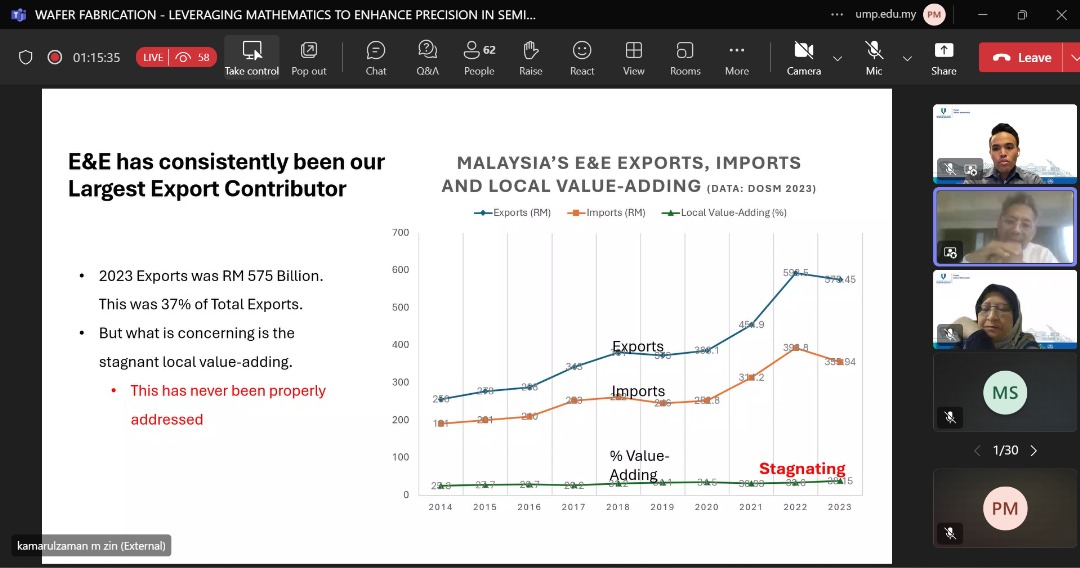

Dr Kamarulzaman highlighted a 4-pronged effort to improve local value-adding in this industry: (I) fostering aspiration, (II) ensuring the availability of capital to scale up front-end activities (R&D&I) through strong collaboration with local universities and polytechnics, (III) promoting public-private financing as practiced by China, Taiwan, and South Korea through strategic business integration in the local E&E industry, and (IV) encouraging local sourcing of supplies from SMEs and developing a supporting ecosystem.

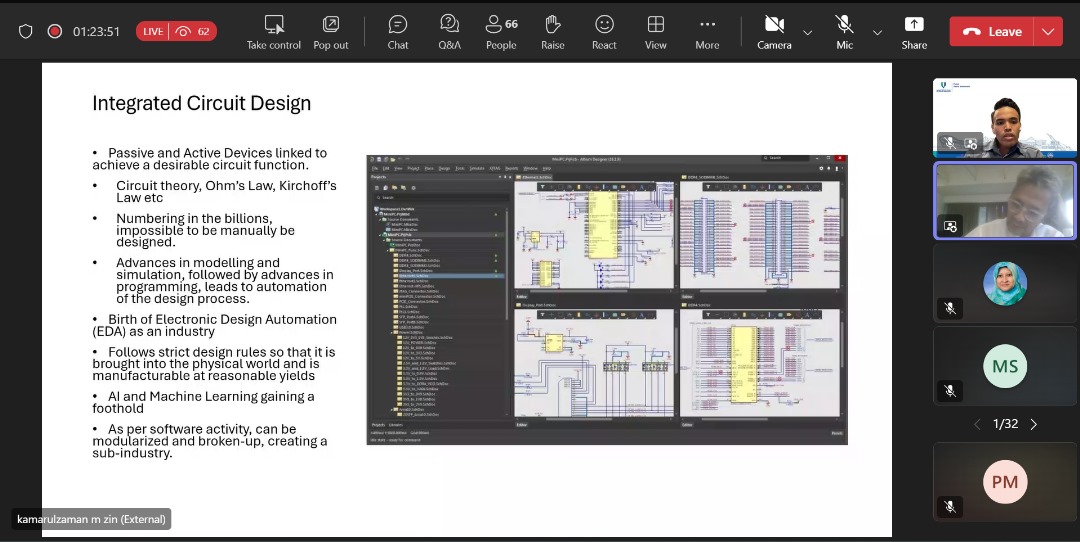

Recently, Malaysia launched the National Industrial Master Plan 2030 (NIMP, 2030) and the National Semiconductor Strategy (NSS) in an effort to position itself as a global semiconductor leader by moving up the value chain towards front-end processes, such as integrated circuit (IC) design and wafer fabrication. Strong competencies in mathematical tools and techniques are essential as foundational knowledge in the semiconductor industry. Mathematics graduates with Technology Computer-Aided Design (TCAD) skills provide the basis for developing Process Development Kits (PDKs), which link design and fabrication to ensure that designs are manufacturable, perform as intended, and are predictable. This approach avoids costly errors and reduces development time, thereby adding precision to semiconductor IC fabrication. Hence, strategic investments in R&D&I, public-private partnerships, and the development of local talent, particularly in mathematical and technological skills, to maintain Malaysia's competitive edge in the global semiconductor market.

Author: Assoc. Prof. Dr Roslinazairimah binti Zakaria